Results

2022 - First stage

High entropy alloys can be obtained under optimal conditions in RAV facilities, working in a high purity argon (Ar 5.3) controlled environment They can be machined and cast into ceramic molds, subsequently welded or heat treated to improve the properties elasticity. The alloy recipes in the CrFeMoNbTaTiZr system were based on the choice of chemical elements with extremely low biotoxicity and which are currently used as the alloying base for classical alloys for the manufacture of medical devices.

In order to obtain high entropy alloys from the CrFeMoNbTaTiZr system in the MRF ABJ 900 vacuum arc remelting facility of the ERAMET - SIM - UPB Laboratory, the following 5 classes of alloys were chosen in which the chemical composition was varied, but the equiatomic proportion was preserved in each of these (see Table 1).

Table 1— Five classes of biocompatible HEA alloys developed for their use as targets.

| Sample name | HEA 2 | HEA 3 | HEA 5 | HEA 6 | HEA 7 |

|---|---|---|---|---|---|

| Chemical composition | CrCrFeMoNbTaTi | CrCrFeMoNbTaZr | CrCrFeTaNbTiZr | CrCrTaNbTiZrMo | FeTaNbTiZrMo |

To obtain the alloys, the raw materials consisting of elements of purity greater than 99.5% were mechanically processed for introduction into the RAV installation, then they were weighed and dosed in equiatomic ratios, as shown in table 2. An attempt was made to keep a constancy of the metal load at the value of about 30 g on each sample.

The chemical composition was determined by EDS analysis which highlighted the fact that the developed HEA alloys have a chemical composition very close to the equiatomic one, the atomic percentages being almost equal. This conclusion is also supported by the distribution map of the chemical elements present in the HEA alloys. The lateral distribution of the chemical elements is homogeneous, including for the chemical elements with a high melting point, such as Ta (3017 °C) and Mo (2623 °C). X-ray diffraction studies have shown that the alloys have a crystalline structure.

In addition, several other alloys with variable Ni composition were synthesized to study the effects of Ni concentration on the crystalline structure and physico-chemical properties of these alloys. Several batches of the AlCrFeCoNix system were fabricated with a nickel molar ratio, x, from 0.2 to 2.0 using the VAR technique. The microstructure of the cast alloy is dendritic. By increasing the nickel content, a refinement of the crystalline grain was observed, as well as a progressive decrease in the microhardness.

X-ray diffraction (XRD) structural analyzes of HEA samples with varying molar nickel content found that the targets maintain the same volume-centered cubic (BCC) crystalline structure for Ni concentration from 0.2 to 1.0, after that a transition occurs, where both BCC and face-centered cubic (FCC) crystal phases are present, starting at nickel contents from 1.2 to 1.6. The observed evolution ends with the targets with the highest nickel contents of 1.8 and 2.0, which exhibit only the FCC crystal phase.

2023 - Second stage

Executive summary of the activities carried out during the 2023 implementation period.

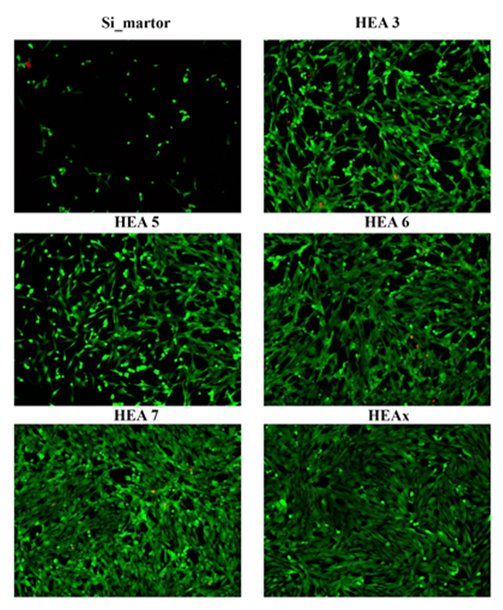

In the second stage of the research project, thin films of high-entropy alloy targets were synthesized, characterized and investigated using pulsed laser ablation and magnetron-assisted radio-frequency sputtering techniques. The most important conclusion, supported by EDS, XPS and RBS investigations, was that in optimal deposition conditions the films had a chemical composition very close to that of the used targets. Also, biological tests have confirmed that numerous chemical compositions used belong to the class of biocompatible materials, being suitable for medical applications.

The PLD deposition method was also optimized by precisely determining the ablation threshold. The role of the laser fluence in the stoichiometric transfer of the target material in the deposited film was thus evaluated and optimized. Both thin film deposition techniques allow the incorporation of nitrogen atoms in metal nitride compounds, which have superior mechanical and chemical properties to those of HEA materials. As the preliminary electrochemistry tests highlighted the positive role of nitrogen atoms incorporated in the structure of the films deposited by laser ablation under nitrogen atmosphere, complex studies were undertaken regarding methods of increasing the nitrogen concentration in the surface area of the thin films as well as improving the chemical activity of these atoms through the quaternization process.

Figura 1. Fluorescence microscopy images that highlight the presence of live cells (green) and dead cells (red) after 24 hours from seeding on the surface of the new coatings intended to improve some medical devices (10X magnification).

The obtained results were included in 4 articles in ISI indexed journals and communicated in five international conferences and an international workshop. Having these data presented, we consider that all the conditions are met for the successful fulfillment of the planned future activities.

2024 - Third stage

Executive summary of the activities carried out during the 2024 implementation period.

In the third stage of the research project we continued the investigations regarding the properties of the HEA films deposited using the optimized conditions determined in the previous years. The research focused on determining the mechanical and biomedical properties of these films depending on the chemical composition of the targets, the method of their preparation (pulsed laser ablation or rf sputtering with Ar ions) without or with the use of a reactive atmosphere of N2 or CH4 for helping the incorporation of nitrogen or carbon atoms in their structure.

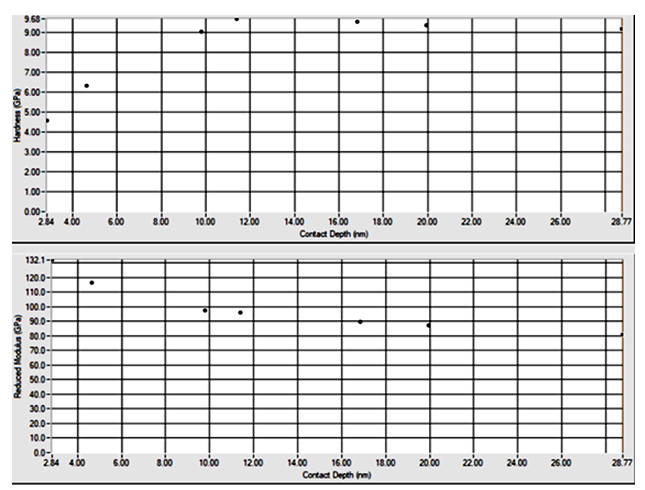

The results of the mechanical wear, adhesion and hardness tests, as well as those for the evaluation of the antimicrobial activity and the inflammatory profile of the endothelium showed that the properties of deposited HEA thin films cover a wide range of values that allows for their usage in different applications.

Figura 2. Hardness and Young's modulus values measured for different loading forces for the HEA film deposited by rf-MS in N2 atmosphere.

For example, HEA films deposited on medical steel 316L indicated nanohardness values of over 7 GPa compared to the steel hardness value of 5.4 GPa. The same HEA film deposited in a nitrogen atmosphere, which led to the incorporation of nitrogen atoms in metal nitride-type compounds, presented a hardness of 9 GPa, almost double that of the substrate. This result convincingly illustrates how the mechanical properties of medical instruments can be significantly improved by using deposited HEA films. As we have shown in the last two activities reports for 2023 and 2024, the biological properties of the coated substrates have been also improved with respect to bare substrate. If we add the results obtained last year, when we showed that the anticorrosive properties of the metallic materials used can be improved by HEA thin film depositions, we can conclude that the deposition of thin films of HEA, in vacuum, nitrogen or CH4 using the pulsed laser ablation technique or radiofrequency sputtering offers a rather wide range of possibilities to improve the general properties of medical instruments for specific applications.